GOLDEN BAY CEMENT

HARDENING UP WITH HARDOX®

Golden Bay Cement wanted extra wear life on their limestone reclaimer’s 180 blades.

By working with Real Steel designers, the blades have now been re-engineered to be stronger and more protected from wear over time – without increasing their weight.

The reclaimer is an impressively large machine that pulls limestone down from a huge stockpile and onto a conveyer belt.

Golden Bay were finding the backing blades on the reclaimer were bending and wearing out too fast. The teeth were individually bolted on and only case hardened – meaning they were much softer on the inside.

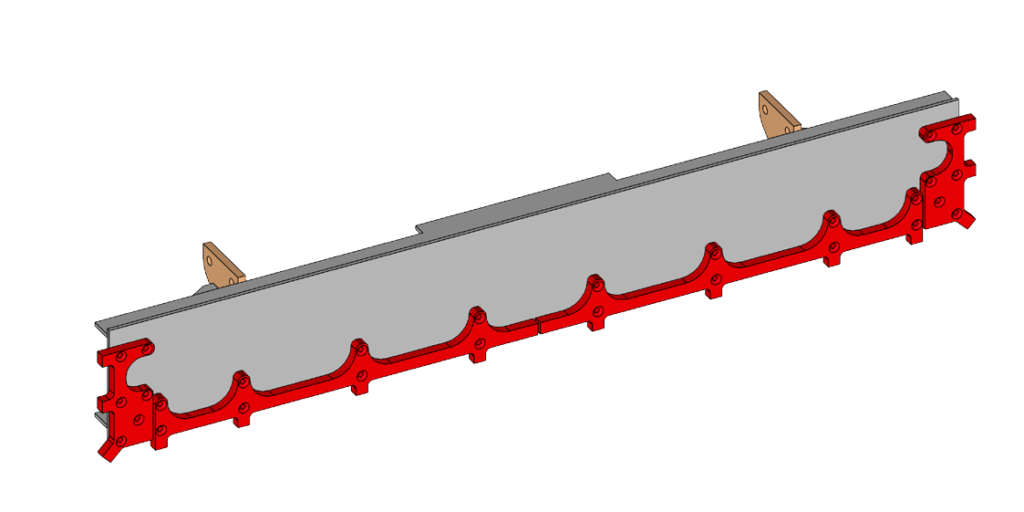

Our Real Steel designers set to work creating a backing blade using Strenx steel to save weight. They added a Hardox bolt-on edge with built-in (rather than individual) teeth, which helped to protect from wear between the teeth. Finally, a scalloped design further reduced the overall weight.

The result is a far superior blade design that is outperforming and outlasting the original part – without adding any additional weight to the reclaimer.

The project is testament to the value of great design, steel selection, and teamwork.

KEY

Grey: Strenx 700MC Plus

Red: Hardox 500

Bronze: Grade 350

Golden Bay Cement are New Zealand’s longest standing cement manufacturer – leading the industry for over 100 years.

Find out more at: goldenbay.co.nz